Committed to Craftsmanship,

Customization & Innovation

At CBF Bakery Systems, we are more than bakery equipment, we are your strategic partner in optimizing your bakery's efficiency and productivity.

Get A Quote 717-793-2941CBF Bakery Systems

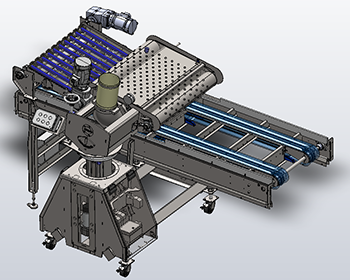

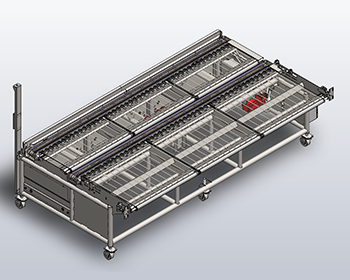

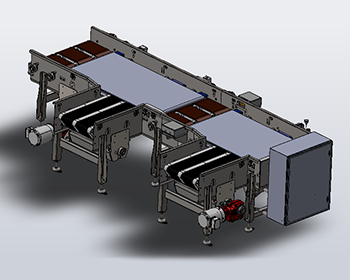

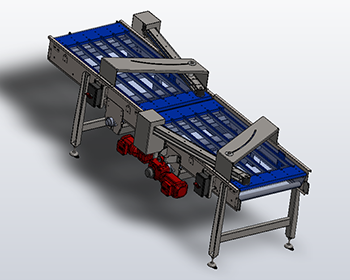

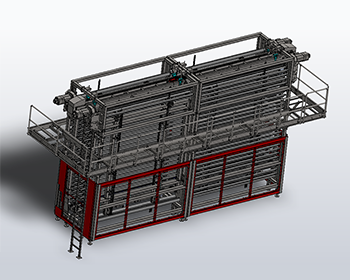

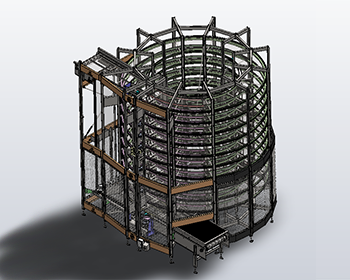

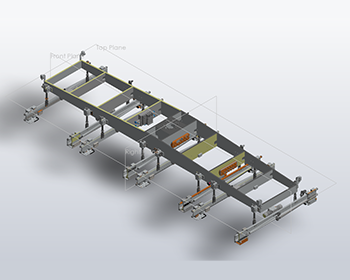

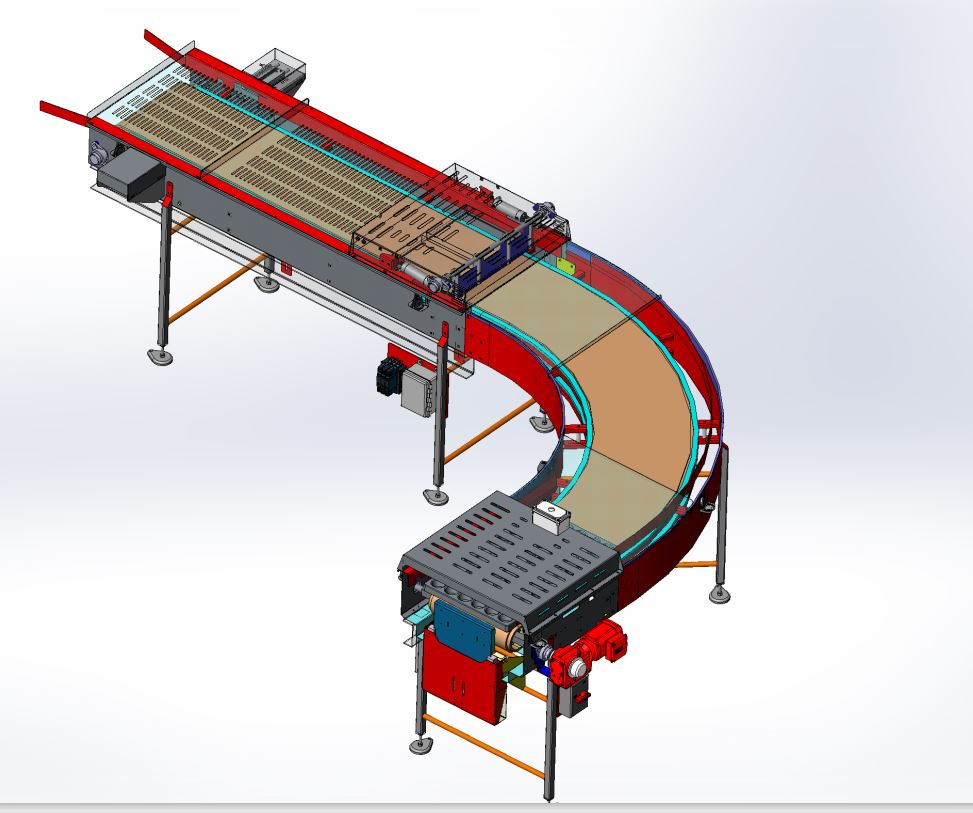

Located in York, Pennsylvania, CBF Bakery Systems specializes in designing, integrating, and manufacturing a comprehensive range of customizable pan and product handling systems for complete bakery production lines. Our solutions cater to a variety of products, including bread, rolls, pies, pizza, muffins, cakes, and more.

Our dedicated engineering staff and project teams are committed to understanding your unique goals, challenges, facilities, and products. By working closely with you, we identify the equipment and features that will enhance the efficiency and output of your production process.

Evolution of Handling Capabilities

Rooted in a history of proprietary designs and engineering advancements, our equipment capabilities have evolved to enhance efficiency, safety, and integration capabilities. From our inception, we have embraced cutting-edge technology and innovative engineering to develop sophisticated handling systems that cater to the ever-changing demands of the bakery industry. This evolution empowers our customers to seamlessly integrate innovative automated solutions into their facilities, ensuring that our clients can consistently produce high-quality goods with maximum proficiency and minimal downtime.

Mission Statement

CBF Bakery Systems mission is to design and manufacture innovative solutions that provide our customers with a product and service unparalleled in our industry.

Engineering Capabilities

Unlocking Engineering Excellence at CBF Bakery Systems

In the world of engineering, CBF Bakery Systems stands as an industry-leader for providing innovative solutions tailored precisely to your needs. Our committed engineering staff and project teams prioritize delivering the ideal solution for your application, ensuring excellence to every step in the design process:

- Collaboration as a Core Principle

- Customizable, Data-Driven Solutions

- Specialization in Turnkey Solutions

- Complete System Design & Integration Capabilities

Manufacturing Capabilities

Your Complete One-Stop Shop for Manufacturing Excellence

We collaborate with you to design and manufacture equipment precisely tailored to your needs and specifications. Here's how we excel in delivering top-notch solutions:

- Precision Through Automation

- Skilled Craftsmanship

- Documentation for Ongoing Reference

- Digital Files & Spare Parts Flexibility

Equipment Overview

- Basket

- Box

- Bucket Style

- Cooling

- Dough

- Free Roller

- Lid

- Packaging

- Pan

- Peel Board

- Power Roller

- Product

- Pick & Place (Single or Dual Head)

- Pick & Place (Gantry)

- Slap Depanner

- Scrabble Depanner

- Standard Inline Unit

- Available with Delidder Option

- Standard Modular Inline (Head, Conveyor, Blower)

- Lid Conveyors

- Pick & Place Delidder (Gantry)

- Standard Inline Unit Delidder

- Dual Overhead Straight Bar

- Hearth Scrabble Loader

- Reciprocator

- Single Overhead Straight Bar

- 45-Degree Load Bar

- Dual Overhead Straight Bar

- Hearth Scrabble Unloader

- Reciprocator

- Standard Unloader

- Single Overhead Straight Bar

- Air Knife (Single or Dual)

- Brush (Single or Dual)

- End Of Arm Tooling

- Mechanical or Magnetic

- Gantry Style

- Pan or Lid

- Robotic Head Style

- Pan or Lid

- Accumulator

- Cooler

- Elevator & Lowerator

- Proofer

- Resting & Retarder

- Cam-Edge Drive

- Depositing Conveyor

- Indexing Conveyor

- Metering Conveyor

- Pan Cooling Tunnel

- Pan Flipper

- Pan Merge

- Pan Switch

- Pan Turner

- Pan Washer

- Product Merge

- Product Switch

- Right Angle Transfer

- Slicer Feed Conveyor

- ThermoDrive Conveyor

Seamless Production Process & Customer Experience

Personalized Customer Service

As a family-owned business, we prioritize personalized customer service, ensuring your unique needs are met with a dedicated approach. As a part of our commitment to customer service, we also provide on-site visits during the production process.

Quality Control Promises

Skilled craftsmen manufacture, assemble, wire, and test equipment prior to shipment, ensuring adherence to specifications and a streamlined installation process.

Service Contracts

Through our nationwide network of millwrights, we offer installation, training, and supervision packages. The benefits of our service contracts include avoiding unplanned downtime and waste, faster emergency response, online remote machine support, improved bakery team knowledge, and the ability to plan downtime, resulting in reduced service costs.

Training & Support

Our after-sales service includes line inspections, maintenance solutions, spare parts delivery, and comprehensive training to maximize your return on investment.

Turnkey Solutions

We provide the technical strength of a global leader combined with the energy, flexibility, and craftsmanship of a family business. Collaborating closely with your team and other high-quality equipment suppliers, we deliver automation that maintains precision, controls quality, and reduces lead times.

Elevate your bakery operations with our expertise!

CBF Bakery Systems stands ready to make your production process more efficient and cost-effective.

To learn more contact us via phone call, email, or link provided.